Start a IML project with you?-Simply give us a call:

+86 596 6797685 or iml@honokage.com.

You can also use our contact form

IML Production site

IML technical Support

A fully dedicated team of experts is available to answer your every question. Support and availability - that is our commitment to you! We are able to work closely with all molders to help you convert to IML technology.

The IML technical support advantages at HONOKAGE:

- Precise: Fully automated controlling using a camera system.

- New materials, new manufacturing processes

- Innovative, highly dynamic process and assembly technology.

Your Form & function

Your design and functionality requirements form the basis of our development work. We work closed to identify your needs and design products accordingly. Specific design for specific solutions.

The product ideas are then transferred to our CAD, UG or PRO-E system and receive the "Final touch".

The design advantages at HONOKAGE:

- Understanding the IML packaging needs of our customers.

- Designing the packages that will serve these needs.

- Creating alternative solutions.

3D Mould design

CNC Machine

Development

We develop specific solutions for our customers by using all our resources. Our focus is on product optimization from R&D to mould manufacturer&maintenance. Quality and cost are firmly under controlled from the beginning.

The development advantages at HONOKAGE:

- Project management

- Qualified engineer

- Inhouse tool

- Small batch testing

- HACCP certificated

- Experienced manufacturer who understand design

Prototyping

For faster and more cost-effective results. We can produce a prototype for your moulded plastic containers and parts.

The prototyping advantages at HONOKAGE:

- The implementation of Rapid Prototyping enables descriptive design, functional and testing samples to be created quickly and cost-effectively.

- Modelling and testing the chosen alternative.

- High efficent produced prototypes

3D printer for prototype

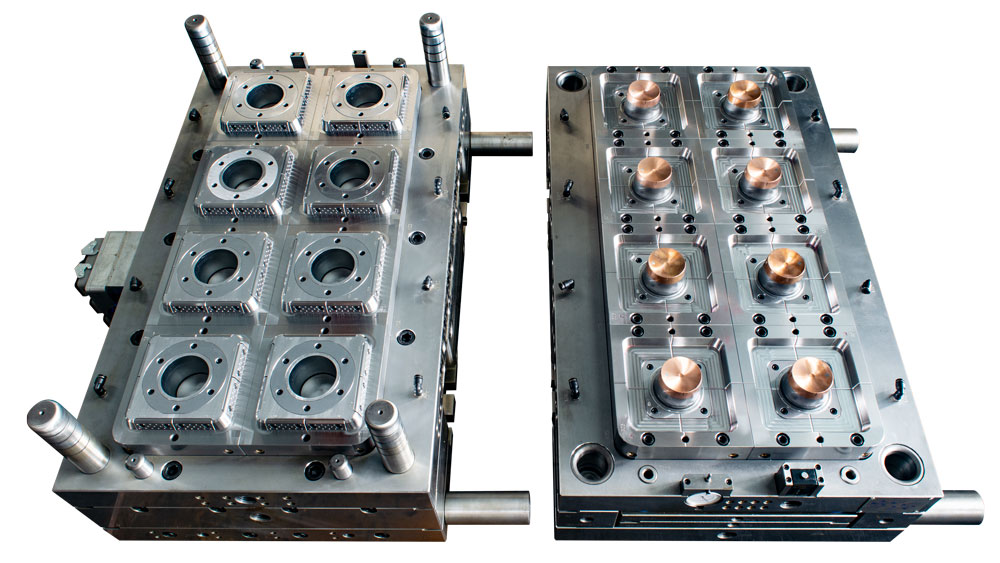

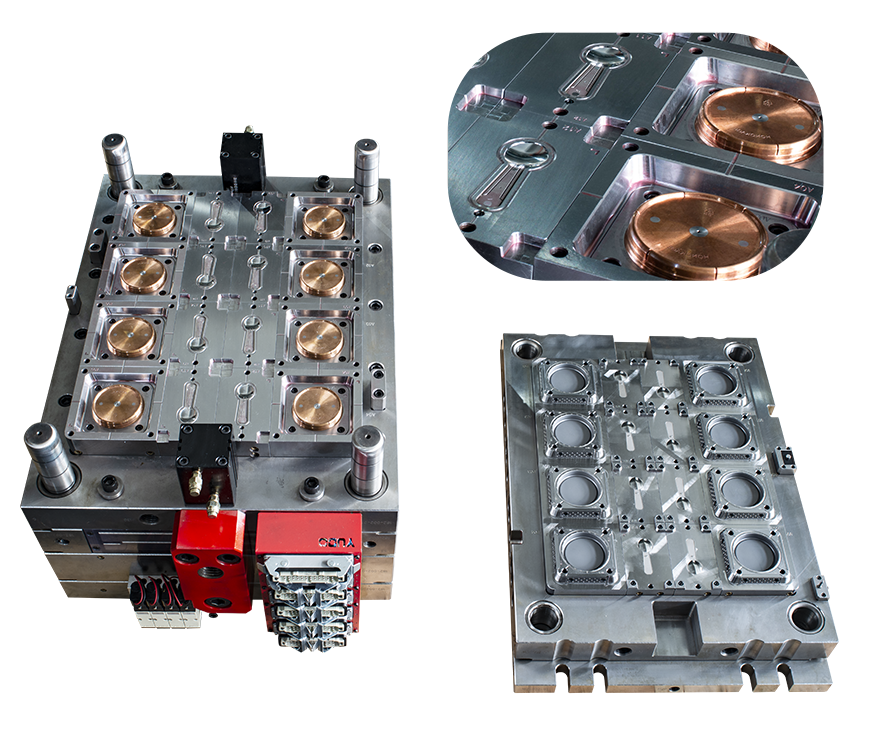

Mould with 8 cavities

Mould making

Our mould construction department is housed in a dedicated facility who have 20 years of mould-making experience, in addition, we use mould flow technology to perfect our tooling design. Our on-site tool room undertakes regular planned maintenance on all production moulds and is able to carry out unforeseen repairs almost immediately.

The Mould making advantages at HONOKAGE:

- In-house mould making for efficient high-end production.

- 20 years experience in tool making of art analysis for perfect mould.

- Our mold construction department is housed in a dedicated facility, so we focus on you.

Productions

HONOKAGE reach global stands in production like BRC, Sedex, ISO. Equipements are imported from German and Singapore. All products have been designed using the latest software to do stack height strength and impact resistance simulation, provide you the most lowest transportation costs.

The productions advantages at HONOKAGE:

- Clean room with BRC standard

- High speed German Injection Machine (Brand: DEMAG)

- Consistent quality and high production output

Mass production for IML food container

Quality control system is implemented according to

BRC requirement

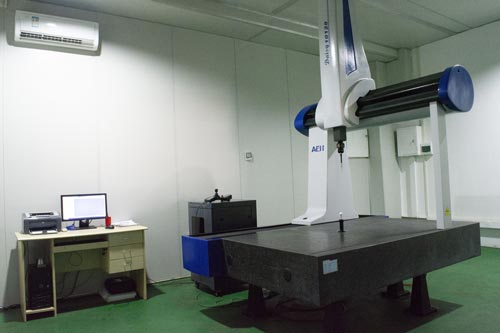

Quality management

Our hygiene and quality policies are determined under the guidance of our BRC and ISO9001 certificates and implemented without any concessions. This way are cooperative partnership becomes a mutual, long-term success.

The quality management advantages at HONOKAGE:

- Independent audit process

- Quality management system.

- Inspection plans simultaneously coordinated with the customer

Logistics

Our sophisticated logistics system ensures that you not only receive your products in the highest of quality but also on time. We endeavor to supply your products bes condition on time. We understand in the supply chains have many mitigating factors, we work closely with you to deliver your product on time in full.

The logistics advantages at HONOKAGE:

- One project one team work support.

- Prepare safety stock material to ensure the production start as plan.

- Fully monitor the goods loading into container.

Inspection and shipping for IML container