About us

Since its establishment in 2003, HENGLONG PLASTIC provides manufacturing and related services in product design, tooling, project management, insert moulding, and in mould labelling(IML) and plastic injections.

HONOKAGE is a brand owned by HENGLONG PLASTIC.

What we can do for you:

HONOKAGE develops, produces and sells a wide range of standard and specialised packaging, with large order quantities and fast delivery times.

Using all our resources ranging from the packaging design to mould production and maintenance, from R&D to the fully equipped mould production workshop, we develop customized solutions for our customers.

Solutions customized to the customer, flexibility, easy function and social responsibility are the values that make us who we are.

Our Services

IML technical Support

A fully dedicated team of experts is available to answer your every question.

Design

Together we design the targeted product optimisation and define the requirement profile.

Development

We develop customized solutions for our customers by using all our resources.

Prototyping

We could produce a prototype for your label and your molded plastic containers or parts.

Mould making

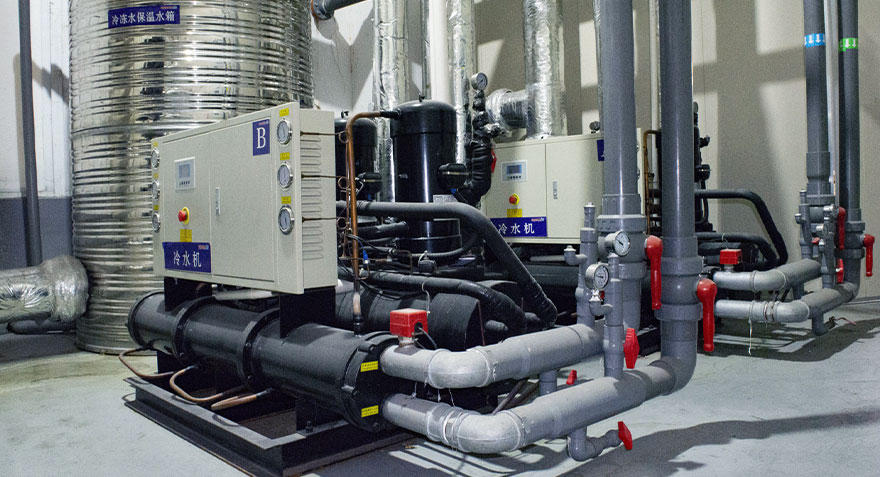

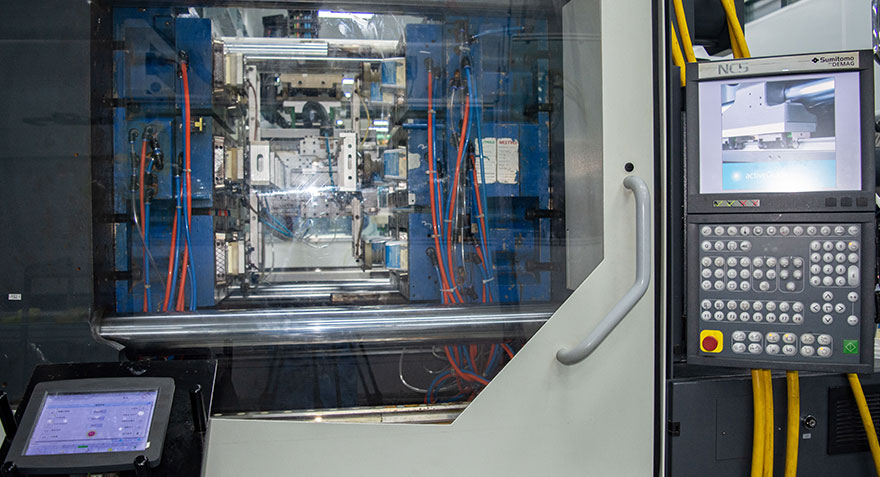

Combining mould flow analysis with 20 years of mould-making experience for error-free production and shorter leading time for tooling making.

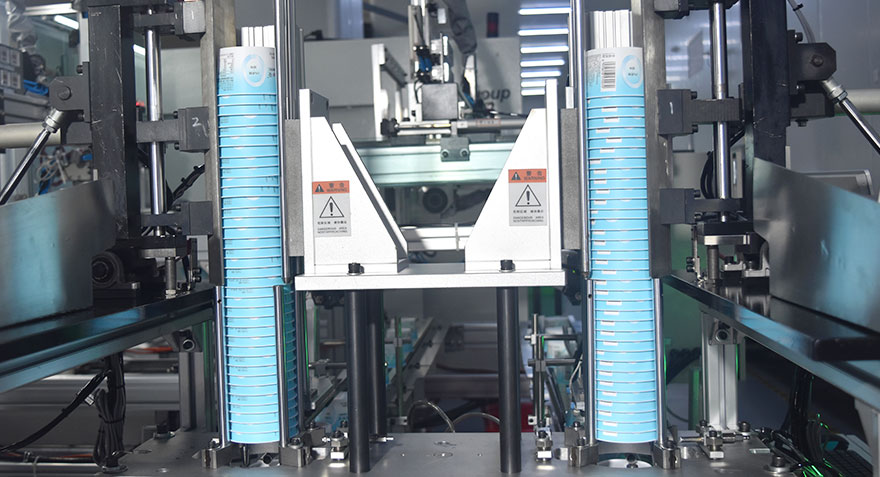

Productions

All products have been designed using the latest software to do stack height strength and impact resistance simulation, provide you the most lowest transportation costs.

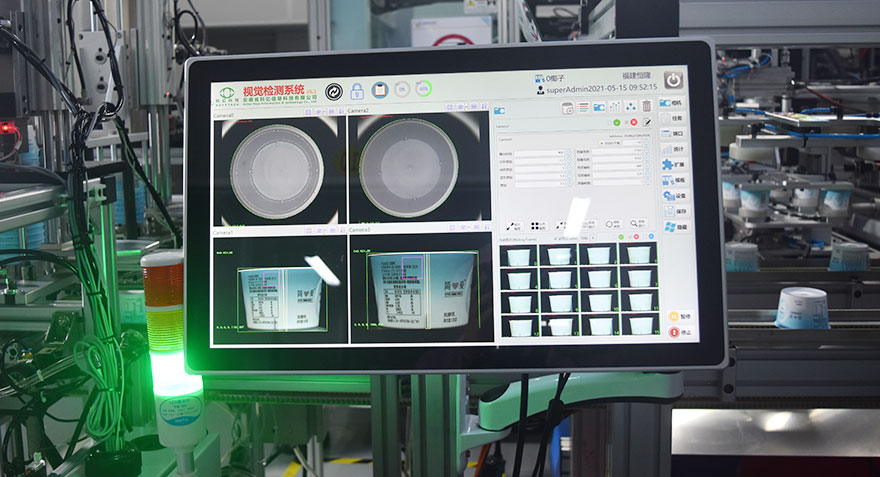

Quality management

Our hygiene and quality policies are determined under the guidance of our BRC and ISO9001 certificates and implemented without any concessions.

Logistics

Our sophisticated logistics system ensures that you not only receive your products in the highest of quality but also on time.

Wordpress themes JazzSurf